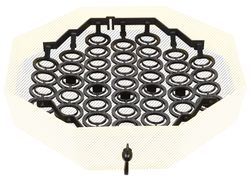

The "CLEO" incubator is used in private households for hatching poultry eggs. It is designed according to the principles of surface incubators, with eggs laid in a single layer. The construction, made of plastic with temperature regulation, ensures uniform stability of the internal temperature. Heating is provided by an electric resistor. Air homogenization in the incubator is ensured by a fan. Temperature control is provided by a thermostat. Through openings in the construction, slow and continuous ventilation of the incubator's microclimate is ensured, thus removing excess carbon dioxide and other harmful gases produced during hatching. Humidity is provided by two small tanks (channels) that are refilled with water: A and B in the lower part of the incubator's construction (see Fig. 1 and 1a). In the first week of hatching, increased humidity is recommended (to prevent water evaporation from the eggs), and in the last two days (to help the chicks break through the membrane). On other days during the hatching period, normal humidity should be maintained to remove excretions. Temperature is the most important factor in hatching. Overheating of eggs leads to anomalies; the chicks will be weak or there will be high mortality within the shell. Insufficient heating slows down embryonic development, resulting in a delayed "hatch". The goal of turning the eggs is to equalize the temperature and humidity across the entire surface of the eggs and to prevent the embryo from sticking to the shell.

0500000036500